Five Reasons to Choose

RebuildLA Home

Fire Safe

Fire-Rated Design Assemblies

SIP assemblies combined with 1-hr fire rated materials such as Fiber Cement siding, stone/stucco or metal cladding, add in Class A tile flooring and fire-rated windows and doors can deliver a fire resistant structure. Essentially you are designing with specific materials that encase a SIP thermal building enclosure that is already fire rated on its own.

No venting of crawl or attic spaces is needed, there by protecting you from aiborne embers.

Exterior Fire-Rated / Fire-Resistant Treatments:

SIPs can also be treated with various fire rated topical treatments to achieve additional fire rating requirements. Contact us, to learn more about the treatments available for your safety.

As wildfires continue to reshape communities and landscapes, the urgency to rebuild stronger and smarter has never been more apparent. Recovering from such devastation requires more than just replacing what was lost—it calls for innovative building strategies prioritizing resilience and safety.

Cost Effective

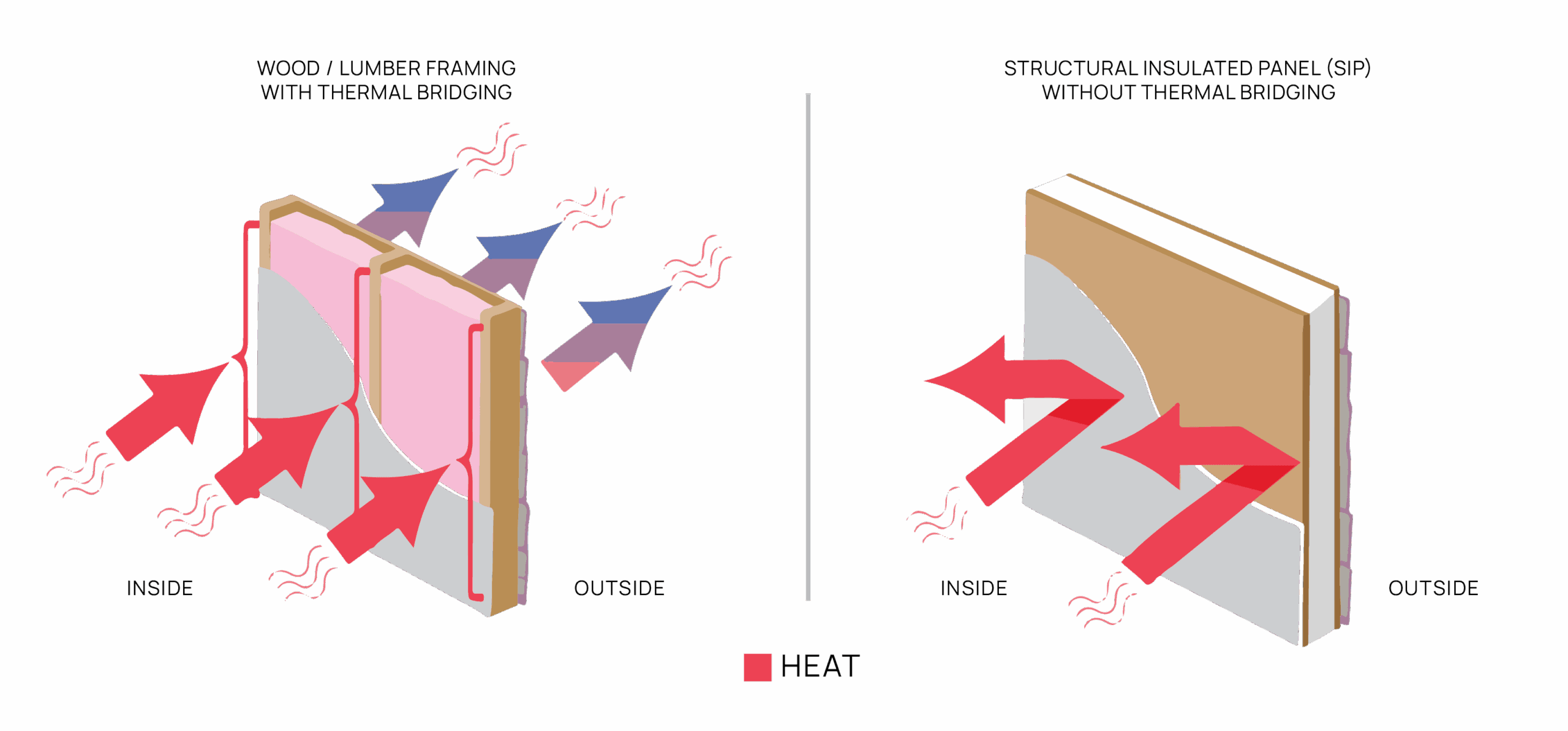

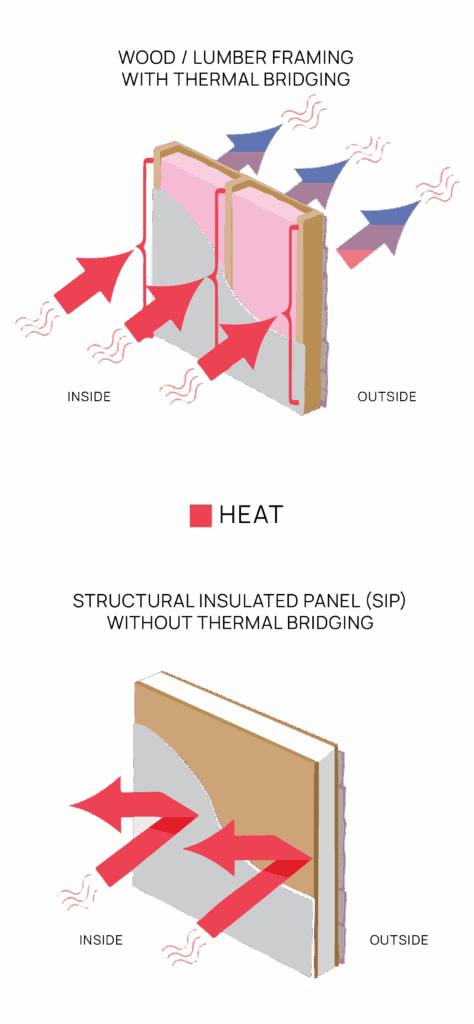

Virtually airtight structural insulated panel framing allows for better control over indoor environmental conditions, reducing the need for heating and cooling output. Notably, SIP structures are 40% to 60% more energy efficient than traditional site framing.

Buildings that use less energy significantly reduce carbon consumption and emissions to minimize pollution. The exceptional R-values and U-factors of SIPs deliver high thermal performance, superior building comfort, and reduced operational costs, including heating and cooling costs.

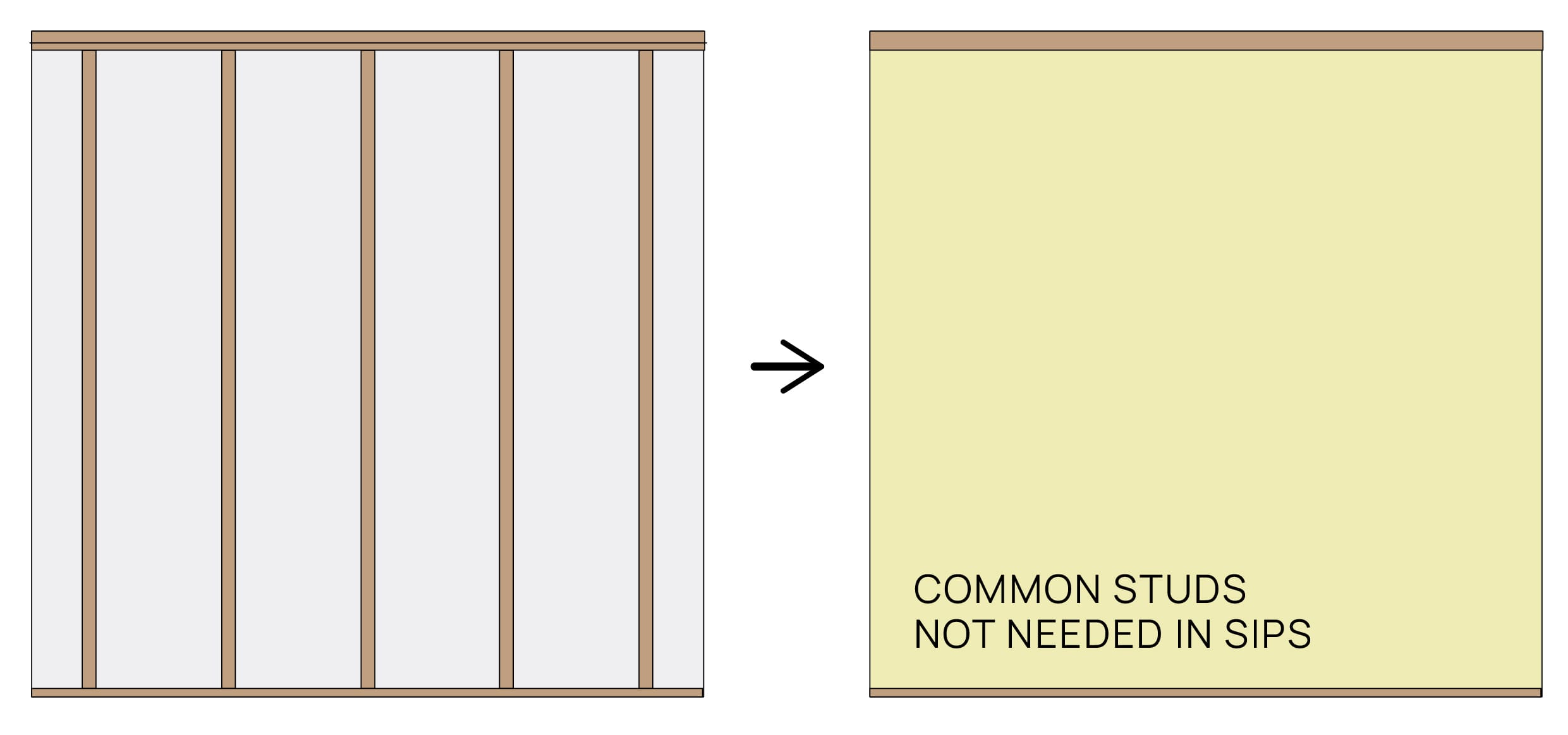

The Amount of Lumber Needed Framing in Assemblies

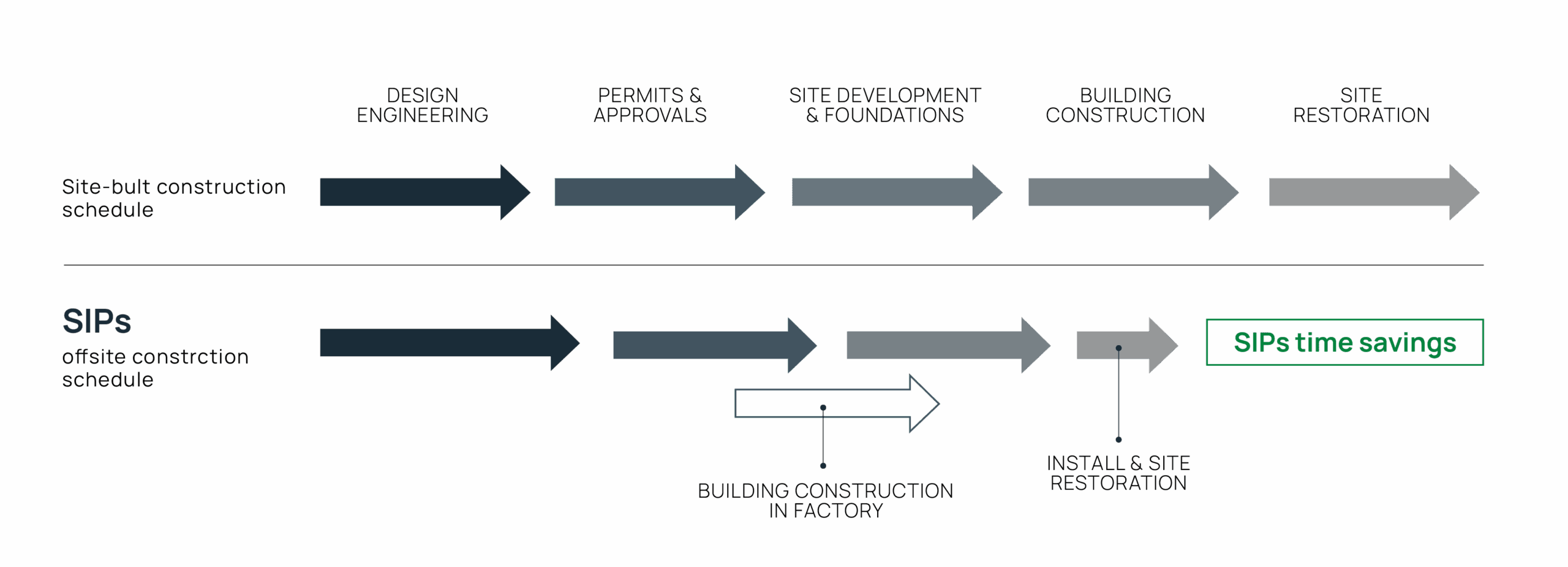

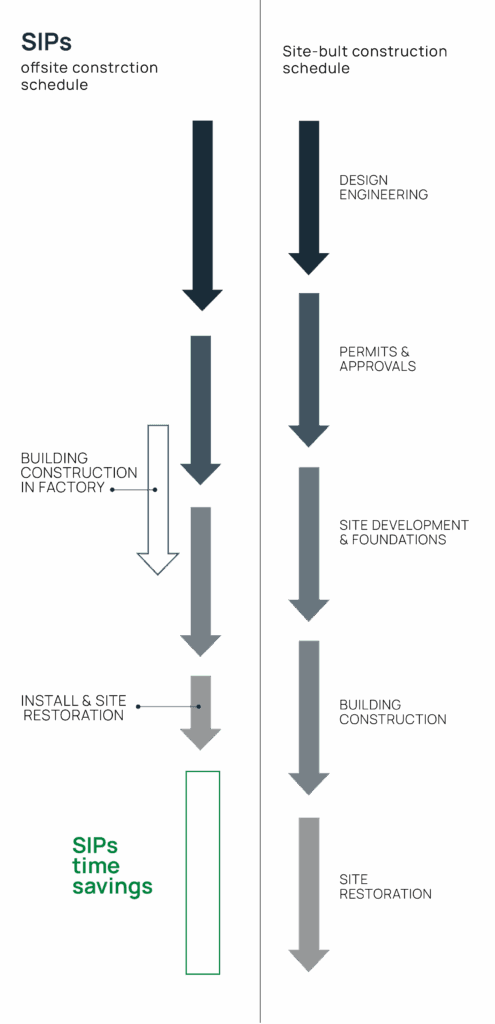

Time Efficiency

Structural insulated panel (SIP) installation requires less time and fewer workers than traditional stick framing, streamlining the construction process and facilitating efficient builds.

Pre-fabricated, pre-cut, pre-insulated, and engineered to be perfectly square and plumb, SIP framing installation requires no special training. With our experienced contractor and his team they can erect SIP frames in around 55% of the time it would take to assemble traditional stick framing, and with fewer workers.

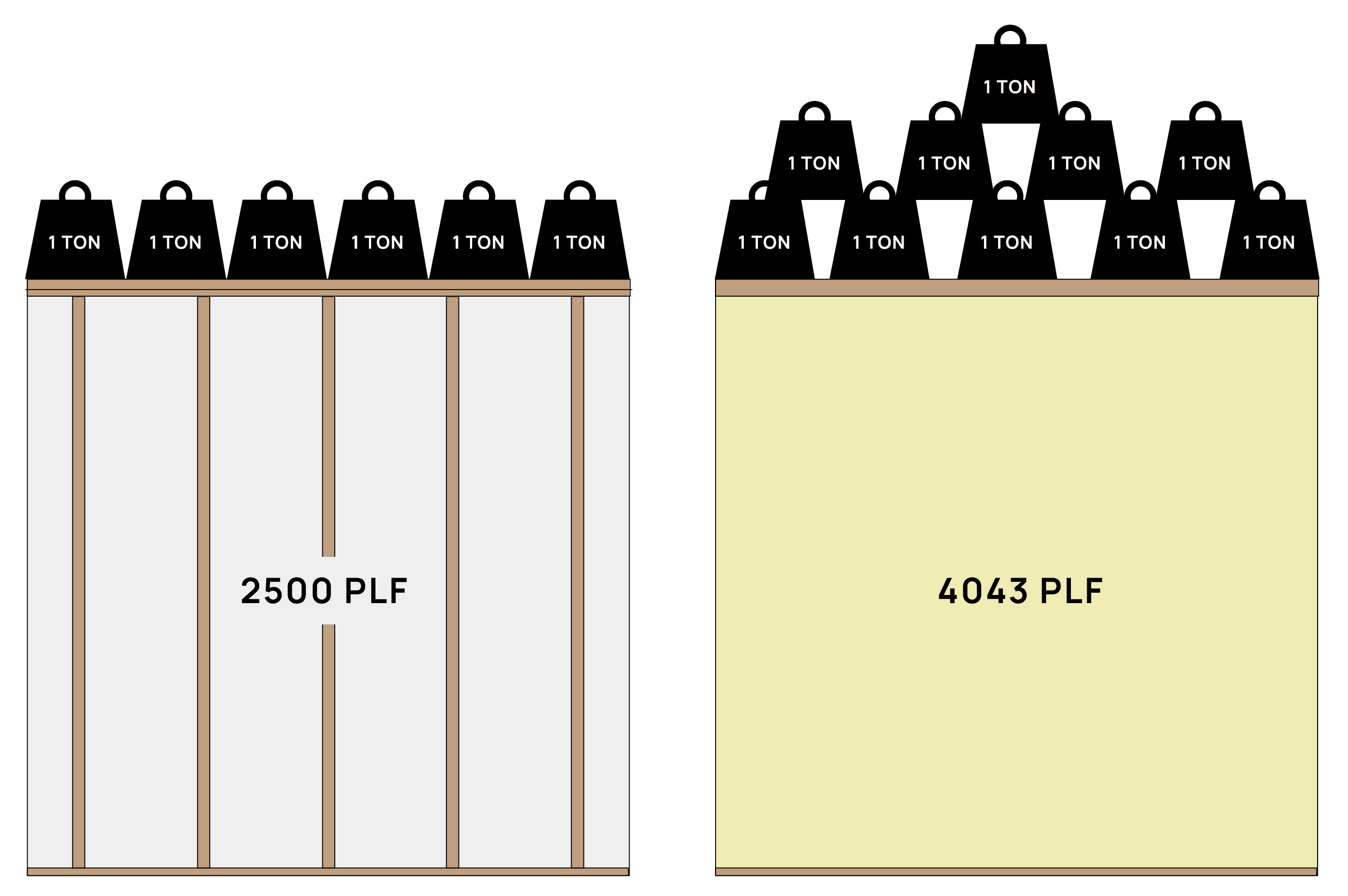

Durable & Strong

Engineered for exceptional strength and resilience, SIPs are ideal for extreme weather and seismic conditions.

With a core of insulating foam sandwiched between two layers of engineered wood, SIPs are 55% stronger than traditional 2×6 lumber, offering superior protection against high winds and seismic activity.

Their strength and weather-tight performance ensure lasting stability and safety in all environments.

2 Tons of vertical uNIFORM load

Sustainable

SIPs are made from renewable resources, as both the oriented strand board (OSB) structural facings and expanded polystyrene (EPS) — or with SIPS MAX, the higher R-value graphite polystyrene (GPS) — insulation are inherently sustainable and 100% recyclable.

These panels also cut jobsite waste by an average of 30%. Utilizing advanced offsite construction technology and automation, SIPS factory fabrication optimizes material use and reduces excessive landfill waste.

Framing Assemblies Thermal Bridging Comparison